Stainless steel processing workshops are equipped with a variety of machinery to ensure that every stage of production, from raw material to finished product, is carried out efficiently.

Here are some common types of equipment you might find in a stainless steel processing workshop:

Melting Furnace: Used to melt scrap steel and ferroalloys to produce stainless steel.

Refining Equipment: Such as vacuum refining furnaces, these are used to remove impurities from molten metal.

Casting Machine: Casts the melted steel into steel ingots for further processing.

Heating Furnaces: Heat the steel ingots or slabs to a certain temperature before rolling.

Rolling Mills: Roll the hot steel ingots or slabs into plates or sheets with the desired thickness and width.

Pickling Line: Removes the oxide layer from the surface of the steel plate in preparation for cold rolling and other surface treatments.

Annealing Furnace: Used for annealing treatment to improve mechanical properties and microstructure of steel plates.

Cold Rolling Mill: Further improves the surface smoothness and accuracy of steel plates.

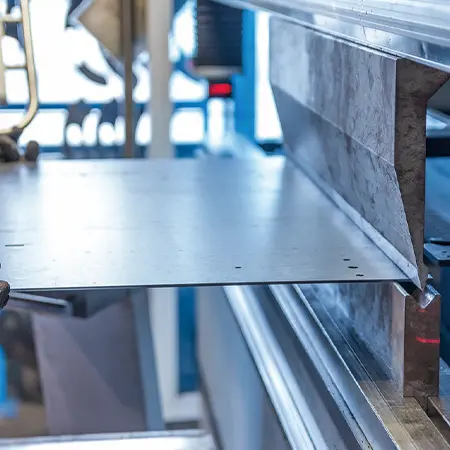

Cutting Machine: Cuts steel plates or sheets to specific sizes.

Polishing Machine: Improves the surface finish and aesthetics of stainless steel materials.

Brushing Machine: Creates a textured finish, like a brushed surface, on stainless steel materials.

Machine Tool Center: Includes various machine tools for precision machining of stainless steel materials, such as cutting, milling, and drilling.

Welding Equipment: Used to join stainless steel materials together to fabricate various products.

Surface Treatment Equipment: Such as sandblasting, polishing, and electropolishing, to improve or alter the surface characteristics of stainless steel.

Cleaning and Drying Equipment: Cleans and dries stainless steel materials after surface treatment.

Coiling and Uncoiling Machines: Used for coiling steel plates into coils or unrolling coil sheets for further processing.

Inspection Equipment: Includes hardness testers, spectrometers, ultrasonic flaw detectors, etc., for testing the physical, chemical, and mechanical properties of materials.

Lifting and Conveying Equipment: Used to move heavy steel ingots, plates, or finished products within the workshop.

Automation Control Systems: Monitor and control various parameters throughout the production process.

The specific equipment configuration in a stainless steel processing workshop will vary depending on the type of products manufactured, production scale, and production processes.

Remember, the workshop should be well-organized and maintain high safety standards at all times since a lot of the processes involve high temperatures and heavy machinery.